One of platinum’s most important uses is as a catalyst – speeding up chemical reactions and improving yields, while remaining unchanged itself in the process. Since the early 20th century it has been used as a catalyst in the commercial production of nitric acid, a key component of fertiliser. It is also essential to the technology that is behind the growing numbers of fuel cell electric vehicles which rely on using a proton exchange membrane coated with a platinum catalyst.

Platinum is used in numerous healthcare treatments and medical devices. Its purity means it is well tolerated by the body and it is radiopaque due to its density, giving high x-ray visibility, especially important in stents and clot-retrieval devices used to treat cardiovascular disease. In addition, it is an excellent electrical conductor when used in pacemakers and cochlear implants. Compounds made from platinum are used in the treatment of many cancers.

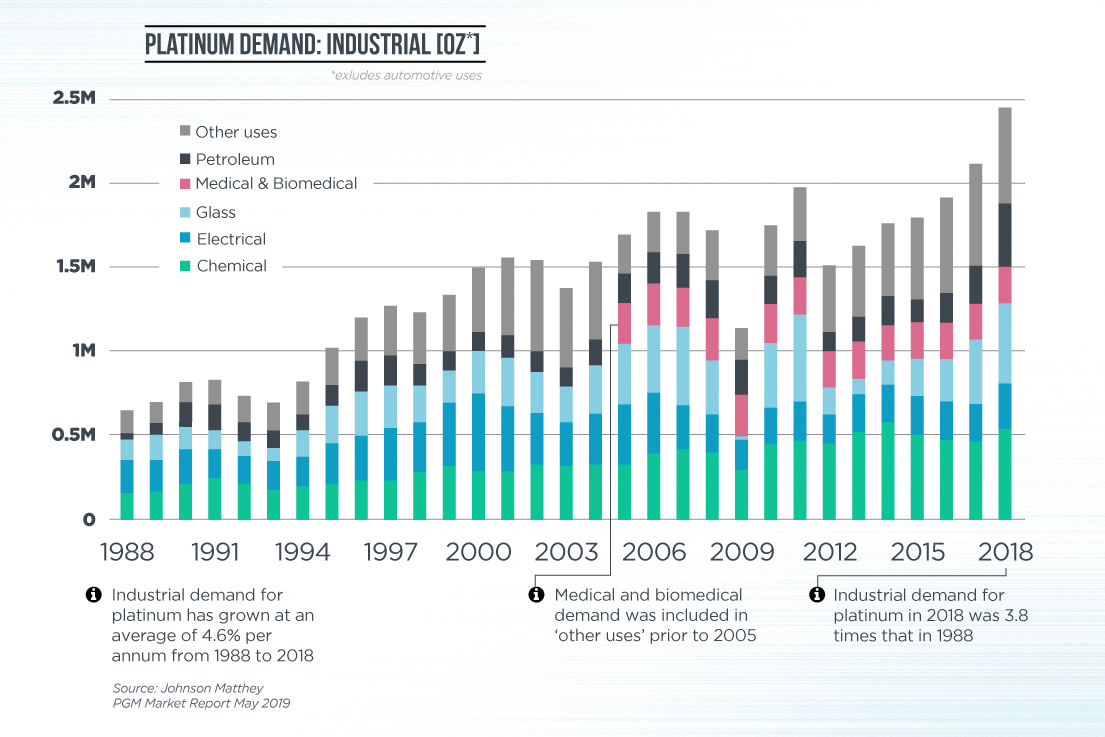

In 2018 net demand* for platinum in industrial uses was 1,910 koz compared to total net demand of 5,450 koz. Industrial demand is expected to again contribute the largest share of net demand in 2019.

*Platinum catalysts in industrial applications usually experience ‘wear’ of a few percent per annum before the entire catalyst is replaced. The worn catalyst is recycled. Annual platinum demand reflects the (relatively small) worn volume only for catalysts in service as well as the (sometimes large) entire catalyst for construction of new plant capacity. Platinum from recycled industrial catalysts is typically used to produce the new catalyst and this process is known as closed-loop recycling. The opposite, or open-loop recycling, would be a recycled car autocatalyst which is sold with the car and only returned for recycling at the end of the life of the vehicle.