Platinum, in conjunction with iridium, is used as a catalyst in Proton Exchange Membrane (PEM) electrolysers that use polymer electrolyte, one of the two leading electrolysis technologies available in the market. A new platinum and iridium-based catalyst – which contains up to 90 per cent less iridium, while performing up to three times better, has recently been developed. This not only reduces costs, making green hydrogen production at the scale envisaged by the EU’s Hydrogen Strategy more affordable, but also removes concerns about the availability of iridium, of which only a small amount is produced annually, ensuring PEM electrolysers remain at the forefront of electrolyser technology as the market expands.

Platinum demand growth

The reduction in the amount of iridium needed in PEM electrolysis is meaningful as it supports the wider adoption of PEM electrolysers and thus increased demand for platinum. Johnson Matthey, the global science and chemicals company, has suggested that PEM electrolysis could achieve a market share of 30 - 60 per cent.

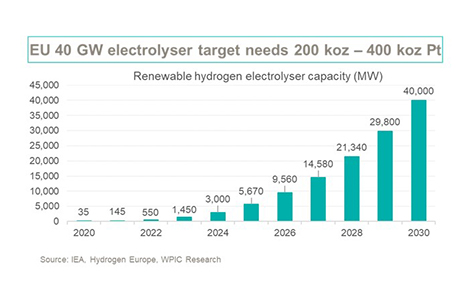

Platinum’s role in the hydrogen economy is crucial both throughout the EU and beyond; it is used in fuel cells for fuel cell electric vehicles, as well as in the production of green hydrogen. The global platinum demand impact of announced green hydrogen policies is clearly sizeable over the longer-term; current EU and China green hydrogen generation capacity targets alone would require, cumulatively, between 300 koz and 600 koz of platinum by 2030*.

*Based on 30% - 60% PEM electrolysers, 90% Heraeus loadings reduction with 0.45gPt and 0.15gIr per kw